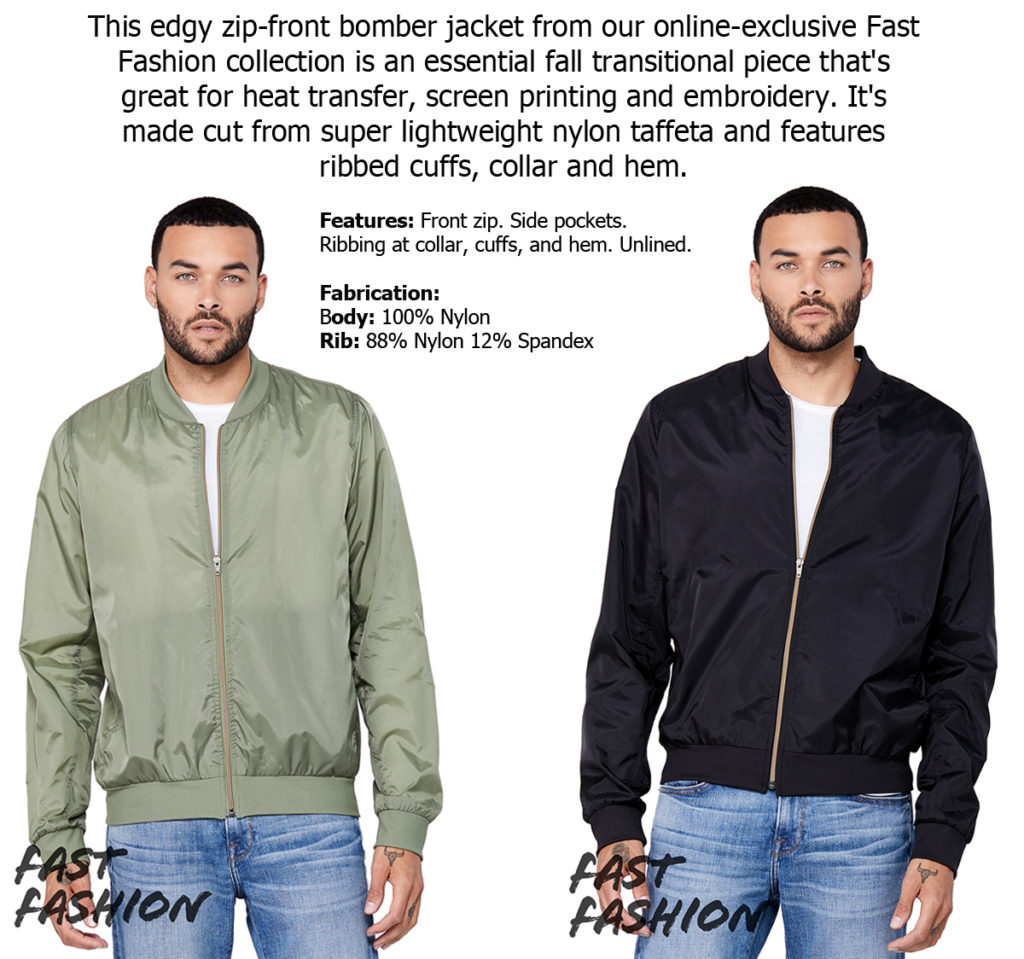

Bella + Canvas: “As you may have heard, we recently launched a lightweight bomber jacket in our Fast Fashion collection that we’re obsessed with. Most bomber jackets are double lined, but just like we do with everything else, we wanted ours to be unique! The BELLA+CANVAS bomber, style 3950, is made of 100% nylon, so it’s super lightweight and consists of a single-layer, making it much easier to print on.

Decorating Tips for Screen Printing

A plastisol screen print is the way to go if you’re printing in bulk. If you’re using a dark color print, like we did in our video with Shirt Agency, you can use just a regular plastisol ink. For a light-colored design, just be sure to use a nylon-safe ink base. Since our bomber doesn’t have a double liner, it lies straight on to the board. Then it’s screen printed, just like any other product is!

Decorating Tips for Heat Press Vinyl

Heat pressing vinyl is another great option for our bomber, especially if you’re decorating for a team! The process is simple, but it’s really important to test the temperature of your machine with this fabric. Since it’s such a thin vinyl, the timing and temperature are key to avoid melting. As you can see in our video, Cole from Shirt Agency, also recommends putting a teflon pillow inside the jacket. This will act as a buffer to ensure an imprint isn’t left from the zipper on the front in the vinyl print. We also recommend spending some time flattening out all the wrinkles in the jacket, just to make sure no creases are created when heat pressing. Since the vinyl is like a sticker, you can easily double check the placement on the garment before pressing it into the fabric. In our video, Cole heat pressed the vinyl for 5 seconds at 317 degrees. This was what he determined was best for his machine. As we mentioned before, be sure to do plenty of testing on your own machine before fulfilling an order!

And that’s it! It’s that simple. Watch the full video to see the final results below.”